Unlock the Editor’s Digest for free

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

Neo Performance Materials has opened Europe’s first mass-scale production facility for rare earth magnets as its chief executive predicted a three-fold increase in demand over the next decade.

Companies on the continent are scrambling to reduce its dependence on Chinese supply chains, and the Canadian group, which started production at its $75mn plan in Estonia on Friday, has signed initial contracts with German auto suppliers Schaeffler and Bosch.

China upended supply chains for minerals crucial to the energy transition when it imposed export controls in April, in retaliation for US President Donald Trump’s tariffs. Despite promises from Beijing to address the issue, European companies are still reporting renewed delays obtaining the export licences.

In an interview, Neo’s chief executive Rahim Suleman said the current demand for rare-earth magnets was “incredibly large”.

“Customer motivations are incredibly high to diversify their supply base and to have . . . localised supply chains,” he added.

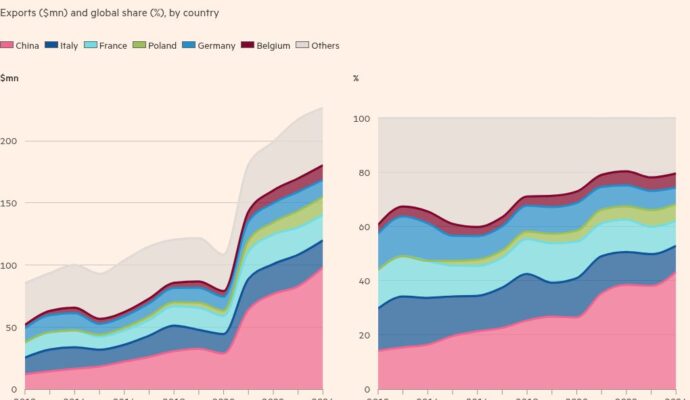

He warned that Europe’s reliance on China for 98 per cent of EU rare earths magnets demand was “untenable” especially with demand set to almost triple in the next 10 years.

The region currently imports 22,000 tons of rare earth magnets but Suleman forecasted that the demand was expected to rise to 60,000 tons. Neo’s new facility will initially produce 2,000 tonnes of magnets each year, ultimately reaching 5,000 tonnes.

The EU has set a target to localise 40 per cent of the processing for critical raw materials, including rare earths, as part of its efforts to reduce dependency on outside suppliers and especially on China.

The new facility was supported by a grant of up to €18.7mn from the EU’s Just Transition Fund and a US$50mn credit facility from Export Development Canada. “The rare earth magnets that will be produced here are indispensable to growth and innovation,” said European Commission president Ursula von der Leyen in a statement, stressing the importance of the facility.

France has become Europe’s leading player in efforts to break dependence on China but there are not enough critical raw material projects on the continent to address soaring demand from carmakers and industrial groups for the magnets.

In the area of magnets, completely squeezing out supply from China was impossible, Suleman said. It was feasible to have 30 per cent of magnet production outside China, compared with its present near total dominance of the market, he said.

Production in Estonia came at a “cost premium” to China but the magnet in an electric motor made up only a relatively small part of the total value of the EV supply chain, he said.

The plant sits close to Neo’s existing facility in Estonia, which separates rare earths from other materials. The raw materials for the magnets would come from suppliers in Australia and Malaysia, among other sources.

The expansion of rare earth mineral processing and magnet production had progressed faster in the US than in Europe, thanks to the subsidies from the US federal government, which were larger as were the tensions between Washington and Beijing.

“In the US, they’re chasing government money, and in Europe we’re chasing customers or customers are chasing us,” he said.